The choice of programming language The management program of the CNC tube bender severally developed by the laboratory is written in a very language. it's a visible platform-based program development tool developed on the idea of early language. visual image may be a thanks to develop a graphical interface. Users not have to be compelled to write a great deal of code to explain the looks of the interface. Instead, simply drag and drop the visually planned objects directly onto the screen in a very visual programming setting. this can be the foremost notable feature. Users cannot solely write a range of applications, however conjointly insert spreadsheets, data processing software package, etc. directly into them. The computer code of the pipe bending machine should initial have an easy and convenient human-computer interaction interface, and show numerous things to be tested and knowledge to be ascertained on the interface. Secondly, it's necessary to finish the communication between the commercial pc and every management unit, that is, the commercial management machine sporadically releases the information acquisition commands to every management unit and reads the information of every management unit. This perform is principally for {the knowledge|the info|the information} acquisition card; produce a info and store the varied collected data for calculation, analysis and preservation. additionally, it supports dynamic knowledge exchange libraries, dynamic link libraries, object linking and embedding, and technology. Dynamic knowledge allows applications to ascertain dynamic electronic communication with different applications, and dynamic link libraries make programs easy to call languages and assembly languages. Or functions, object linking associate degreed embedding techniques enable different numerous based mostly applications to be joined or embedded as associate degree object into an application and manipulated. At a similar time, its event-driven programming mechanism makes the program style simple, intuitive to scan, realizes the human-computer interaction between the user and also the machine, provides operation and show device standing data, and is incredibly convenient to use. additionally, the system has sturdy management capabilities. With knowledge controls and management windows, you'll directly produce or manipulate a formatted info and supply powerful knowledge storage and retrieval capabilities. These characteristics of the language build the look flow of the CNC tube bending machine system software package straightforward and clear, numerous functions area unit convenient to implement, and also the development cycle is brief, that the CNC tube bending machine system software package is written in language.

News

The choice of programming language The management program of the CNC tube bender severally developed by the laboratory is written in a very language.

Check the realm round the operating place of China hydraulic semiautomatic pipe bending machine to get rid of any rubble that interferes with work and traffic. There should be no oil on the bottom to avoid slithering. The stack of work-pieces ought to be neat and tidy to forestall collapse and injury.

1) Check the realm round the operating place of China hydraulic semiautomatic pipe bending machine to get rid of any rubble that interferes with work and traffic. There should be no oil on the bottom to avoid slithering. The stack of work-pieces ought to be neat and tidy to forestall collapse and injury.

2). Check if the protecting device on the hydraulic CNC pipe bending machine is in condition. If it's not put in, it's not allowed to drive. The intermediate frequency bender ought to have smart grounding and electrical insulation, and therefore the voltage ought to be stable.

3). Check the lubrication space. once the oil is brief and oil-free, the oil ought to be else.

4). once the empty automobile is running, check whether or not the mechanical operation is traditional, and whether or not the controller is sensitive and straightforward to use. when everything is ok, work again.

5). once 2 individuals work an equivalent time, they have to join forces closely and coordinate. someone ought to be allotted to work the switch. it's not allowed to speak to people throughout operation to forestall malfunction.

6) The operator should not leave the machine once the machine is started.

7). throughout operation, nobody is allowed close to the bend vary of the pipe, and a protecting warning call is about. Stabilize the tube to forestall it from being scraped by the pry bar. The operator will solely stand on the skin.

8). Correct the tube to listen to the protection of the encircling space. Use the steamed buns 1st to immerse within the water; for a number of minutes, forestall the handle from being wounded. don't wear gloves once knock.

9). once hot bending and correcting the tube, the face ought to avoid the nozzle to forestall the recent sand from being hurt once the tube is vibrated. once filling the yellow sand, the pipe ought to be fixed to forestall marketing. There ought to be no oil within the pipe, and dry yellow sand ought to be used.

10). once fastening the pipe into the rack and untie the lead wire, it ought to be soft to forestall squeeze and crushing. Handling pipes ought to listen to pedestrians to forestall individuals from being hurt.

11). once exploitation the gas, 1st open the chamber door, come off the accumulated gas and so ignite.

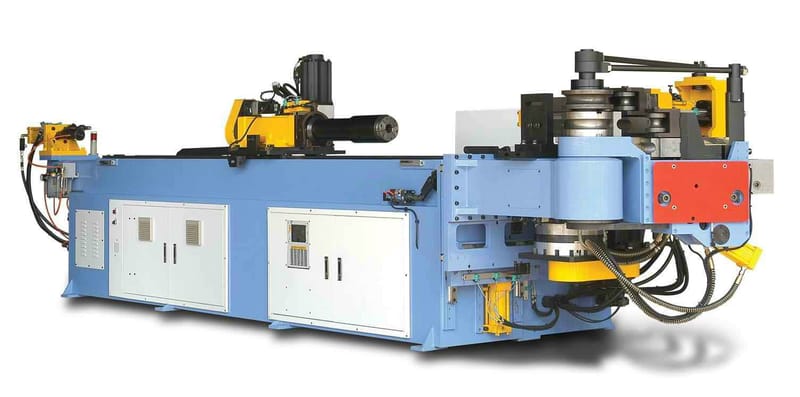

The establishment and management of all key setting parameters of cnc automatic hydraulic pipe bending machine, controlled by CNC (clamping, die pressing, mandrel, CLR), fixed or variable radius bending. Increased capacity to 200%% thanks to the VGP3D generated by the advanced work cycle.

The establishment and management of all key setting parameters of cnc automatic hydraulic pipe bending machine, controlled by CNC (clamping, die pressing, mandrel, CLR), fixed or variable radius bending. Increased capacity to 200%% thanks to the VGP3D generated by the advanced work cycle.

Real-time, automatic simulation of a piece while it's programming. Component feasibility checks and generates the most appropriate duty cycle (time and cost), highlights possible collision risks, and automatically selects the most efficient avoidance route. By simply entering the component bending coordinates, the complete NC program is a graphical simulation. Particularly suitable for straight bending between them, ELECT XL is mainly used in construction machinery, industrial vehicles, and in branches such as railways, shipbuilding, automobiles, motorcycles, hydraulic pipes. The material of the elbow is mainly stainless steel, aluminum tube, copper tube, iron tube. From the equipment, there are manual bends and sluggish bends (hydraulic). Thin-walled elbows with small diameters (below 19) may be implemented on manual pipe benders. The special pipe fittings for the medium pipe diameter (20-50) are mainly equipped with hydraulic and medium frequency pipe bending machines.

The large pipe diameter (50---90) pipe bending machine was originally the first if the car intake, exhaust gas is trivial. Large pipe diameter (more than 100), the first for large trucks, pipelines and pipes for extraordinary needs.

Metal processing plants that use China pipe bender currently face some complex problems, and the high cost of raw materials makes each piece of blank a must. The quick response and the willingness to change the operation mode of the bending forming section to meet the current needs of the sheet metal processing plant can reduce the preparation time.

Metal processing plants that use China pipe bender currently face some complex problems, and the high cost of raw materials makes each piece of blank a must. The quick response and the willingness to change the operation mode of the bending forming section to meet the current needs of the sheet metal processing plant can reduce the preparation time.

This results in greater production capacity and reduced scrap rates. Developing and implementing well-designed Sops, making better use of storage and inventory systems, leveraging machine functionality and leveraging human resources are ways to help bend molding shops increase efficiency and productivity. The CNC pipe bending machine is mainly composed of three parts: mechanical part, hydraulic system and PLC control system. The mechanical part mainly consists of a pipe clamping device, a bending pipe transmission device, a boosting device, a bed body and a bending pipe mold. The working principle of the elbow is as shown in the figure: the elbow mold is fixed on the main shaft and rotates with the main shaft. The tube is fixed on the clamping groove of the fan-shaped elbow mold by the clamping mold, and the movable auxiliary guiding material is controlled by the sliding groove. Attached to the outside of the bend of the tube blank, when the bend mold is rotated by an angle.

The tube is wound around the circumference of the bending die, and the angle of rotation of the bending die is the bending angle. The three-dimensional multi-bend of the same radius realized on one pipe member mainly has three major actions: linear feeding, space rotating pipe and bending pipe.

The difference and difficulty between this system and traditional single head hydraulic pipe bending machine is that the system can meet the needs of different condensers with bending radius R50, R60 and R70 respectively. Second, when all the bending parts at one end are formed automatically, the bending parts at the other end can be bent automatically by turning the head, and the condenser products with both ends bent can be removed from the bending roll. The main purpose of U-turn is to reduce the radius of curvature that has been bent with bending action. Three, we can bend different angles according to the different requirements of each bending part.

The difference and difficulty between this system and traditional single head hydraulic pipe bending machine is that the system can meet the needs of different condensers with bending radius R50, R60 and R70 respectively. Second, when all the bending parts at one end are formed automatically, the bending parts at the other end can be bent automatically by turning the head, and the condenser products with both ends bent can be removed from the bending roll. The main purpose of U-turn is to reduce the radius of curvature that has been bent with bending action. Three, we can bend different angles according to the different requirements of each bending part.

By adjusting the center distance between roller 1 and roller 2 and replacing the roller connecting plate, it is possible to meet the needs of different condensers with bending radius of RS0, R60 and R70 respectively. The open roller is also allowed to turn and bend, and the condenser product at both ends is bent out of the bending roll. In order to bend different angles according to the different requirements of each bending part, we adopt the combined limit mechanism which has been successfully developed in the process of long-distance positioning, and meet the requirements of bending different angles according to the different bending parts.

In order to improve the reliability of the system, we adopt a closed-loop control method with a terminal position sensor for all actions. Compressed air is used in all power parts and the cylinder is used as the action actuator. The double electric control reversing valve controls the movement of the cylinder, so that each action has a memory function. The main control part adopts high-performance programmable logic controller. In the design of control program and control circuit, all kinds of complex situations in the process of equipment adjustment and operation are fully considered. Whenever power failure or gas failure occurs, the program state is remembered by the holding counter and the holding status register. When the program is called and the gas supply is restored, the operation can be resumed. Caller instantaneous dual-electronic control reversing valve maintains the state of gas path before power cut and gas cut, and starts the next state transition condition until the corresponding action reaches the end of stroke and the position sensor has signal, then carries on the corresponding follow-up action, so as to avoid waste products due to power cut and gas cut. In order to meet the needs of different products, corresponding control programs are designed for different types of main condenser parts. When replacing condenser parts, the corresponding control program can only be switched by using a selector switch.

Most of China pipe bending machine manufacturers are settled within the middle of the economic chain for a protracted time. The front-end R&D and back-end sales can play a decisive role in dominant the complete chain, whereas the intermediate producing links ar in a very passively controlled position. this can be conjointly one in all the drawbacks of introducing technology.

Most of China pipe bending machine manufacturers are settled within the middle of the economic chain for a protracted time. The front-end R&D and back-end sales can play a decisive role in dominant the complete chain, whereas the intermediate producing links ar in a very passively controlled position. this can be conjointly one in all the drawbacks of introducing technology.

For example, within the go, there's an aphorism of “Golden Corner grass Grass Tummy”. within the producing trade, the technology analysis and development finish of the economic chain head is that the most powerful and profitable a part of the economic chain; the second is that the tail of the economic chain. Sales and after-sales service; the last is that the process and producing position within the middle section, the management is that the weakest, and also the adventitious price is that the lowest, and most of China's enterprises are settled within the most embarrassing position.

China's little automatic pipe bending machine makers are varied, that has caused the matter of poor analysis strength. The technology or patents researched in universities are tough to be accepted by little enterprise makers due to their value, that ends up in our automatic bending. The tube machine technology has stagnated, creating our product additional and additional out of the particular higher needs. Of course, little businesses don't desire to relinquish up the technology analysis and development facet. However, below sure objective factors, it's tough to urge this a part of the profit.

Sales and after-sales service are the foremost intense competition for little businesses. With the event of technology, sales channels have begun to extend, like e-commerce technology. the web may be a excellent information tool. The search site's bidding and improvement target the competition of assorted SMEs. Its main advantages are small investment and large returns. But such resources are limited.

Processing and manufacturing For small enterprises with CNC automatic pipe bending machines, the main technical and quality gaps are not large, and in the end they often evolve into price wars. Of course, these manufacturers are not willing to see. In summary, if you want to get core competitiveness, you can't give up the R&D innovation.

Fully automatic CNC pipe bending machine series standard models have one-layer mold and multi-layer mold two categories: one-layer mold model has a total of 7-axis servo motor control.

Fully automatic CNC pipe bending machine series standard models have one-layer mold and multi-layer mold two categories: one-layer mold model has a total of 7-axis servo motor control. They are: Y-axis feed pipe, angle B-axis, C-axis bending pipe, U-axis clamping die, U1-axis guide die, V1-axis guide die auxiliary thrust, V-axis mandrel. There are 9-11 axis servo motor control for the multi-storey mold. They are: feed Y axis, transfer B axis, bending C axis, head horizontal displacement X axis, head up and down displacement Z axis, clamping U axis, guide U1 axis, auxiliary thrust V1 axis, mandrel V axis. It can amplify the tenth axis and the eleventh axis; the guiding mold moves the Z1 axis and the pipe clamp to grab the G axis.

Selection of solenoid valves for pipe bender 1. The fluid in the applicability pipeline must be consistent with the medium calibrated in the series of solenoid valves selected.

Selection of solenoid valves for pipe bender

1. The fluid in the applicability pipeline must be consistent with the medium calibrated in the series of solenoid valves selected. The temperature of the fluid must be smaller than the calibration temperature of the solenoid valve. Solenoid valve allows liquid viscosity generally below 20CST, greater than 20CST should be noted. When the working pressure difference is less than 0.04 MPa, the direct-acting and step-by-step direct-acting type such as ZS, W, ZQDF, ZCM series should be selected; when the minimum working pressure difference is greater than 0.04 MPa, the pilot (differential pressure) solenoid valve can be selected; the maximum working pressure difference should be less than the maximum demarcation pressure of solenoid valve; generally solenoid valves are unidirectional, because of This should pay attention to whether there is a reverse pressure difference, if there is a check valve installed. When the fluid cleanliness is not high, the filter should be installed in front of the solenoid valve. Generally, the solenoid valve requires a good cleanliness of the medium. Pay attention to the flow aperture and nozzle aperture; solenoid valve is generally only controlled by two switches; conditions permit the installation of bypass pipe for easy maintenance; water hammer phenomenon to customize the opening and closing time of solenoid valve adjustment. Attention should be paid to the influence of ambient temperature on the solenoid valve power supply current and power consumption should be selected according to the output capacity, power supply voltage is generally allowed to be around + 10%, it must be noted that AC starting VAs higher.

2. Reliable pipe bender solenoid valve is divided into normally closed and normally open two kinds; generally choose normally closed type, power on, power off and close; but in a very short time to choose normally open type when the opening time is very long. Life test, factories generally belong to type test items, to be exact, there is no professional standards for solenoid valves in China, so choose solenoid valve manufacturers carefully. Action time is very short, when frequency is high, generally choose direct acting type, large diameter selects fast series.

3. The safety of the general solenoid valve is not waterproof, when conditions do not permit, please choose waterproof type, factory can be customized. The maximum nominal pressure of solenoid valve must exceed the maximum pressure in the pipeline, otherwise the service life will be shortened or other accidents will occur. All stainless steel type should be used for corrosive liquids, and plastic king (SLF) solenoid valve should be used for strong corrosive liquids. Explosion-proof products must be selected for explosive environment. 4. Economy has a lot of solenoid valves can be used in general, but on the basis of meeting the above three points should choose the most economical products.

A few years ago, the accuracy of the cnc pipe bending machine was not the main contradiction. Because the process of bending is not so much science, it is better than art. Machine repeat ability is more important. When the setting is satisfactory, the bending machine only needs to repeat the bend. Nowadays, the materials are expensive and the batch size is small. Aircraft manufacturers must look for machines that can be accepted for the first time. Therefore, the first step in producing a good product is to have a sophisticated machine.

A few years ago, the accuracy of the cnc pipe bending machine was not the main contradiction. Because the process of bending is not so much science, it is better than art. Machine repeat ability is more important. When the setting is satisfactory, the bending machine only needs to repeat the bend. Nowadays, the materials are expensive and the batch size is small. Aircraft manufacturers must look for machines that can be accepted for the first time. Therefore, the first step in producing a good product is to have a sophisticated machine.

The benefits of some precision cnc pipe bending machine are obvious. If the tube is produced for the first time, the productivity will increase and the defective rate will drop. Some of the benefits are not obvious: if a factory has several bending machines, as long as the machines are sophisticated, the bend data of the good work pieces can be shared. This is an important difference between accuracy and repeat ability. A single machine can be repetitive, producing the same product at the same time with the same data; but a group of machines must be sophisticated in order to produce the same product on the same data on any of the machines.

Rotary pull elbows are commonly used in the aircraft industry, where the tubes are formed along a rotating bending die. The production process is relatively simple: pipe positioning, bending, pipe to the next bend position. The accuracy of the bending machine can be divided into three curved tube forming axes: the bending length (DBB), the bending plane (POB), and the bending angle (DOB).

A typical aircraft conduit linear requirement is +/- .010 inches. However, due to the long length of the conduit, it is more realistic to specify the basic accuracy and then accumulate tolerances per foot. The accuracy of modern CNC cnc pipe bending machines is +/- .004 inches, plus an accumulated tolerance of +/- .001 inches per foot. Repeatability is +/- .004 inches for the entire length.

The accuracy of the two rotating axes of the aircraft quality cnc pipe bending machine is +/- 0.01 degrees and the repeatability is +/- 0.05 degrees.

There are several designs on the CNC bending machine to ensure these high precision. On the C-axis, the feedback element (usually a high-resolution encoder) is mounted directly on the elbow arm to directly read the position. On small cnc pipe bending machines, if the encoder is likely to interfere with the pipe, it can be operated by parallel links. The bearings at the joints must have very small tolerances to reduce migration and maintain accuracy.

The B-axis of the bending machine is usually driven by several stages of speed reduction mechanisms. The feedback encoder is mounted on the last stage drive shaft to optimize accuracy and repeatability.

The Y-axis of the bending machine has special problems. Aircraft ducts are much longer than other industries. The most efficient positioning methods are gears and racks. To achieve an accuracy of +/- .001 inches per foot, precision ground racks, high quality gears and direct drive feedback must be used.

Another design requirement for a precision bending machine is that the servo system of the positioning shaft must be "hard". The movement of the mechanical components must be minimal and the electronic servo loop must be positioned and maintained within the required tolerances.

There are other factors that affect the accuracy of the workpiece when using a very precise bending machine. These process variables include various material properties and dimensional tolerances, tooling and tooling settings, lubrication, and weld location.

The working principle of the elbow of China single head cnc pipe bending machine is shown in the figure: The elbow mold is fixed on the main shaft and rotates with the main shaft. The movable auxiliary guiding material chute is closely attached to the curved outer side of the tube blank. When the bending tube mold is rotated by an angle, the tube is wound around the circumferential direction of the bending tube mold, and the rotation angle of the bending tube mold is the bending angle.

The working principle of the elbow of China single head cnc pipe bending machine is shown in the figure: The elbow mold is fixed on the main shaft and rotates with the main shaft. The movable auxiliary guiding material chute is closely attached to the curved outer side of the tube blank. When the bending tube mold is rotated by an angle, the tube is wound around the circumferential direction of the bending tube mold, and the rotation angle of the bending tube mold is the bending angle. The three-dimensional multi-bend of the same radius realized on one pipe member mainly has three major actions of linear feeding, space rotating pipe and elbow, that is, after completing a bending, the pipe is sent to the next bending position and rotated through a space angle. Then proceed to the next bend to obtain a space bend with the same bend radius. The bending mode determines the bending radius. The pipe is fixed on the clamping groove of the fan-shaped bending die by the clamping die. The numerical control pipe bending machine is mainly composed of three parts: a mechanical part, a hydraulic system and a PLC control system. The mechanical part mainly consists of a pipe clamping device, a bending pipe transmission device, a boosting device, a bed body and a bending pipe mold.

The design and manufacturing level of power station boilers has been improved from time to time, with the rapid development of China's power industry. New furnace types are constantly appearing. The demand for the number and specifications of various curved molded pipe fittings in the boiler manufacturing industry is increasing from time to time. The patterns are refurbished from time to time, and higher requirements are placed on the accuracy of the pipe bending and the quality of the exterior. When the old design single head cnc pipe bending machine is processed, it can only complete one bending at a time, often loading and unloading, and the production efficiency is low, and the simultaneous improvement of the output and the quality cannot be achieved. The application of PLC single head hydraulic pipe bending machine control system overcomes the defects that the relay contact control system is susceptible to environmental interference, high failure rate and difficult maintenance. In addition, you only need to modify the software to adapt to the changes in the new process requirements.

The high-performance medium-sized pipe bender used in single head hydraulic cnc pipe bending machine is used in shipbuilding, boiler, truck transportation, and general engineering piping, etc. High performance small pipe benders are suitable for mass production or standardization of products, such as steam, locomotive and other parts, such as exhaust pipes, cushions, bumper all the iron pipe furniture, etc.

The high-performance medium-sized pipe bender used in single head hydraulic cnc pipe bending machine is used in shipbuilding, boiler, truck transportation, and general engineering piping, etc.

High performance small pipe benders are suitable for mass production or standardization of products, such as steam, locomotive and other parts, such as exhaust pipes, cushions, bumper all the iron pipe furniture, etc.

Performance of uni-axial hydraulic pipe bender:

1, the nose and elbow are exquisitely designed to provide maximum elbow space.

2, PLC control, dialogue input.

3, the large capacity cooling circulation system makes the machine running more stable.

4, with manual, automatic, half cycle, full cycle and other functions of arbitrary choice.

5, slow positioning function, repeat ability accuracy of 0.1.

6, mold replacement is simple and convenient, easy to flexible production.

7, mobile foot switch, with automatic start, emergency stop, emergency continue to three functions, high safety.

The China CNC pipe bending machine must be well grounded, and the wire must not be less than 4mm2 copper cord. It is not allowed to access the power supply voltage exceeding the specified range. The plug-in cannot be plugged in. The control loop cannot be tested with a meg-ohmmeter, otherwise the device may be damaged.

1. The China CNC pipe bending machine must be well grounded, and the wire must not be less than 4mm2 copper cord. It is not allowed to access the power supply voltage exceeding the specified range. The plug-in cannot be plugged in. The control loop cannot be tested with a meg-ohmmeter, otherwise the device may be damaged.

2. When plugging or unplugging the connector, the wire or cable cannot be pulled to prevent the solder from pulling off.

3, proximity switches, encoders, etc. can not be hit with hard objects.

4. You cannot use a sharp object to collide with the display unit.

5. The electrical box must be placed in a ventilated place, and it is forbidden to work in dust and corrosive gases.

6, can not be installed and changed to PC input and output.

7. The motor steering must be reconfirmed when changing the power of the bender.

8. The pipe bending machine should be kept clean. In particular, it should be noted that there should be no foreign objects in the sliding grooves such as clamping blocks and sliders.

9. Regularly add lubricant to the chain and other sliding parts.

10. The power must be disconnected during cleaning and maintenance.