Application of numerical control technology in single head pipe bending machine industry

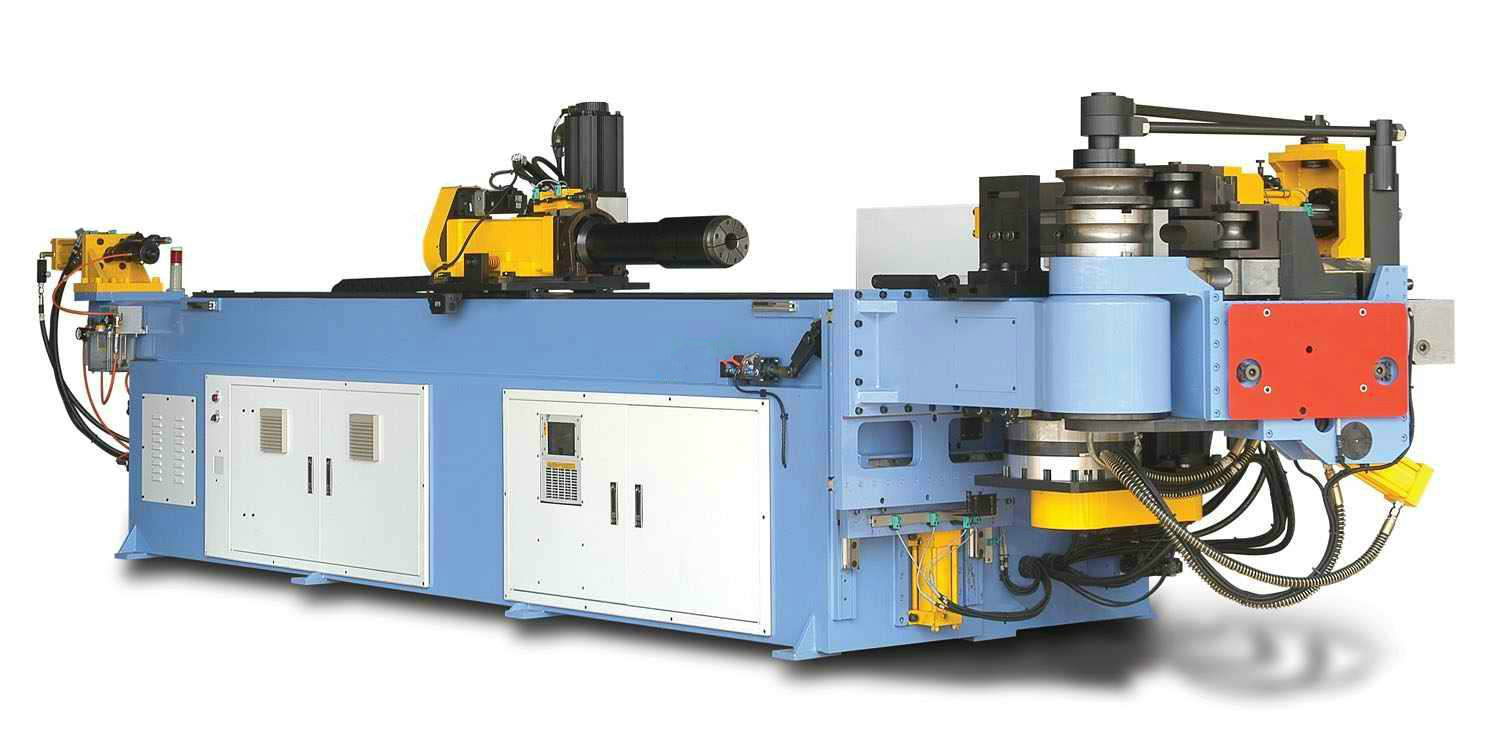

The working principle of the elbow of China single head cnc pipe bending machine is shown in the figure: The elbow mold is fixed on the main shaft and rotates with the main shaft. The movable auxiliary guiding material chute is closely attached to the curved outer side of the tube blank. When the bending tube mold is rotated by an angle, the tube is wound around the circumferential direction of the bending tube mold, and the rotation angle of the bending tube mold is the bending angle. The three-dimensional multi-bend of the same radius realized on one pipe member mainly has three major actions of linear feeding, space rotating pipe and elbow, that is, after completing a bending, the pipe is sent to the next bending position and rotated through a space angle. Then proceed to the next bend to obtain a space bend with the same bend radius. The bending mode determines the bending radius. The pipe is fixed on the clamping groove of the fan-shaped bending die by the clamping die. The numerical control pipe bending machine is mainly composed of three parts: a mechanical part, a hydraulic system and a PLC control system. The mechanical part mainly consists of a pipe clamping device, a bending pipe transmission device, a boosting device, a bed body and a bending pipe mold.

The design and manufacturing level of power station boilers has been improved from time to time, with the rapid development of China's power industry. New furnace types are constantly appearing. The demand for the number and specifications of various curved molded pipe fittings in the boiler manufacturing industry is increasing from time to time. The patterns are refurbished from time to time, and higher requirements are placed on the accuracy of the pipe bending and the quality of the exterior. When the old design single head cnc pipe bending machine is processed, it can only complete one bending at a time, often loading and unloading, and the production efficiency is low, and the simultaneous improvement of the output and the quality cannot be achieved. The application of PLC single head hydraulic pipe bending machine control system overcomes the defects that the relay contact control system is susceptible to environmental interference, high failure rate and difficult maintenance. In addition, you only need to modify the software to adapt to the changes in the new process requirements.