Hydraulic tube bending machine is one of the commonly used equipment for bicycle occupation and electric bicycle occupation. According to the different bending pipes, it can be divided into a large type of pipe bending machine on the handlebar, a pipe bending machine on the frame, and a hanger bending machine. According to different constructions, the pipe bending machine can be divided into a cored pipe and a coreless pipe. In the bicycle and electric bicycle production occupation, the coreless pipe bending skill is generally used, because the core bending machine and the coreless bending machine are There must be differences in the price, and there must be a difference in the tortuous processing and capital.

The cored bender is detailed in:

1. Before the elbow is bent, it is necessary to expand the mouth to remove the cutting tube socket, otherwise the mandrel can not be inserted.

Second, the demand inside the pipe is smooth;

Third, the core rod penetration requirements are higher, conditioning trouble. However, in the process of bending, sometimes the interval between two adjacent curves is small, such as: the pipe on the hanger, etc., at this time, the coreless roller elbow is still selected, and the positioning clamping device and the outer roller are presented. The wheel lacks the condition of the installation space.

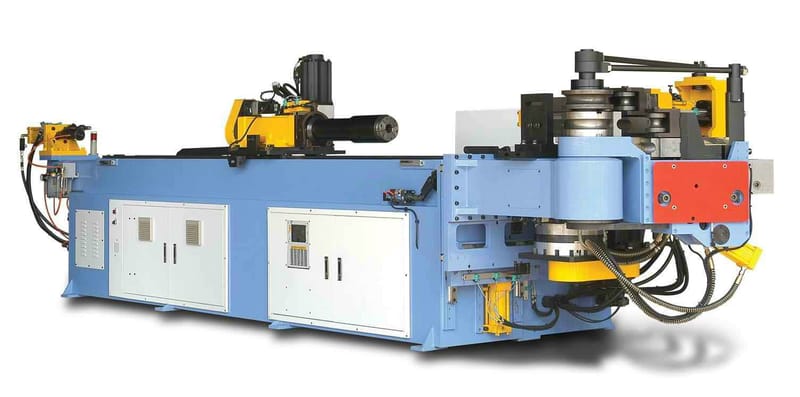

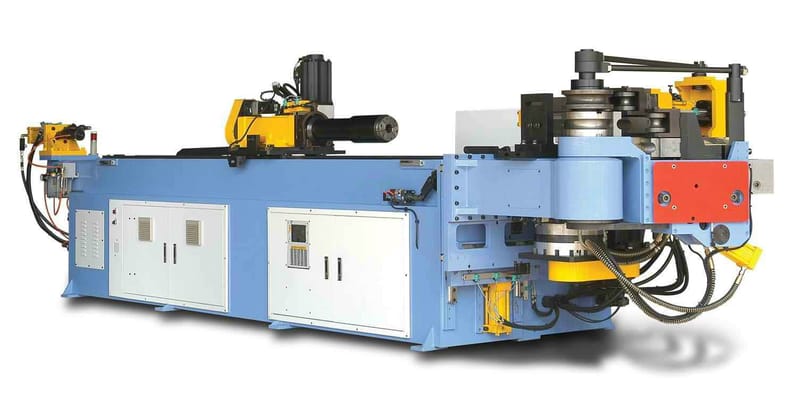

For example, the linear interval between the two curves is 72mm. It is impossible to use the conventional coreless roller hydraulic pipe bending machine. Generally, the cored hydraulic pipe bending machine is used. In order to deal with the above difficulties, we designed a CNC coreless automatic pipe bending machine. This is indispensable for the selection of coreless bends in the case of dealing with two adjacent bending moments.

The overall structure of the machine operating principle, the operation is convenient and fully automatic input, CNC control, very accurate and efficient. The tube blank is laid flat on the two groove plates 4, and the compression cylinder 1 drives the punch 3 to be pressed. The tortuous part is controlled by a rack and pinion servo motor, and the zigzag inversion is controlled by a servo motor. The tortuosity has high precision.