When it comes to pipe bending machines, you may find it strange. However, some elbows are common in our days, and these elbows can be said to be a product under the bender.

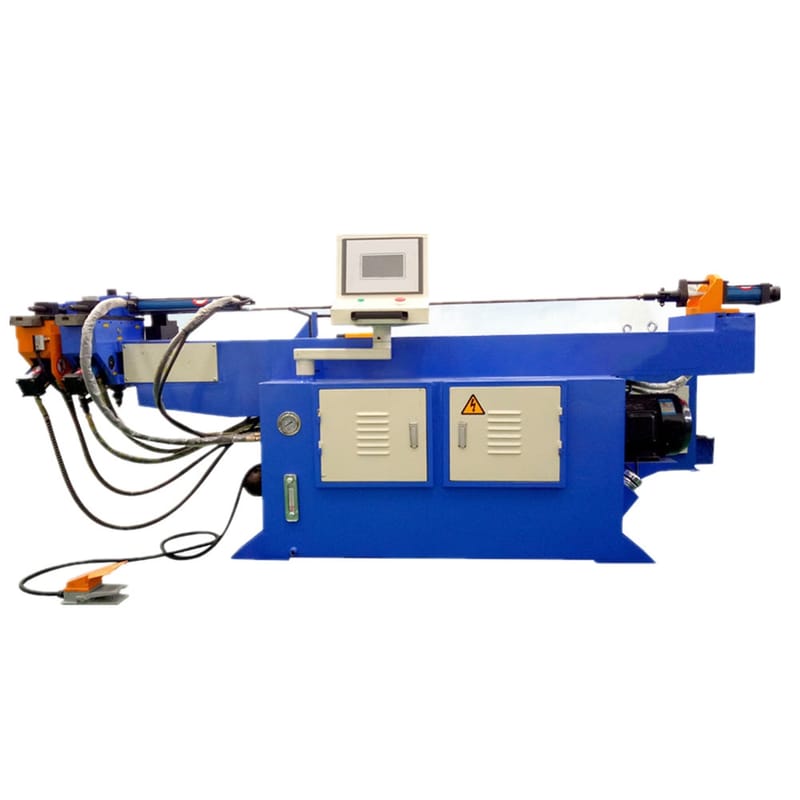

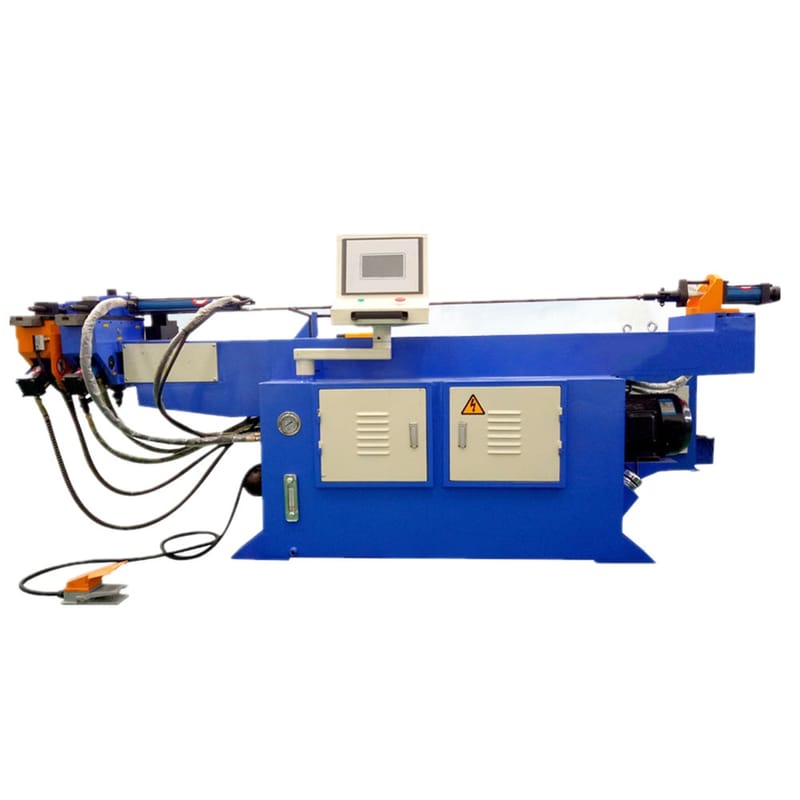

Pipe bending machines can be roughly divided into CNC pipe bending machines, hydraulic pipe bending machines and the like. It is mainly used for electric power construction, public railway construction, boiler laying and repairing of boilers, bridges, boats, furniture, decoration, etc. It has many advantages such as multi-function, reasonable structure and simple operation.

There are many types of pipe bending machines. They are divided into bending type, roll bending type, wrap type and kneading type according to the zigzag form. According to whether the heating is in the case of twists and turns, it can be divided into two types: bending type and hot bending type; The difference can be divided into mechanical transmission and hydraulic transmission.

The bending machine has certain dangers in the time of application. Therefore, Xiaobian reminds everyone to pay attention to safety. Today, I will share with you the problems that need to be paid attention to when operating the bending machine.

When the machine is started, keep in mind that the human body must not enter the range of the swivel rotation. When the machine is working, all personnel stop the space that enters the swivel arm and the pipe is swept. The hydraulic system of the machine tool uses YA-N32 general hydraulic oil. Under normal circumstances, it is replaced once a year. It is necessary to clean the oil filter at the same time. When adjusting the mold, the adjuster should adjust the button by himself. Do not adjust it on the machine. The other person operates on the control cabinet. When adjusting the machine or emptying the vehicle, the core rod should be removed. The hydraulic system also needs to pay attention to the magnitude of the pressure during operation.

Others stop the thrust speed of the side push in the manual condition is greater than the line speed of the edge of the rotating mold. After using the machine for a period of time, you should check the tightening degree of the chain and insist that the upper and lower chains are tight together. In the core-torcing mode during automatic operation, it is necessary for the operator to ensure that the core is inside the tube before the bending arm comes back, or to ensure that the mandrel is not blocked when the bending arm comes back, and the core or the core rod is bent or broken. .