In the pipe processing machinery industry, our customers are first and foremost in the production and processing of pipes. In these enterprises, depending on the nature of the company and the way in which the products are produced and processed, our products to be processed are different, so In terms of equipment model selection, it is also necessary to customize and match the model according to the customer's specific requirements. Nowadays, the pace of intelligent machining of CNC pipe bending machine to the future market is accelerating. The future market trend is definitely the era of intelligent machine tools. In the field of pipe processing industry, how can we increase the number of processing and reduce the labor cost more efficiently? The development idea of the pipe bending machine enterprise. China's transition from a manufacturing power to a high-end industry to create a new power transition. It is necessary to go step by step to the high-end intelligent era according to the needs of the national conditions.

CNC machining pipe, pipe cutting machine, tube shrinking machine and other pipe processing machine tools are highly mechatronic products. They are suitable for processing many kinds of small batch parts, pipes with complicated structure and high precision requirements, profiles, Bending and cutting of materials such as profiled materials require frequent modification of parts, expensive parts that are not allowed to be scrapped, parts that require precision reproduction, urgently needed parts that require shortened production cycles, and parts that require 100% inspection. CNC metal circular sawing machine and CNC tube shrinking machine have attracted the attention of the world with its excellent flexible automation performance, excellent and stable precision, and agile and diversified functions. It has created a precedent for the development of mechanical products to mechatronics. . Therefore, numerical control technology has become a core technology in advanced manufacturing technology. The characteristics and application range of CNC machining tools make it an important equipment for the development of national economy and national defense.

In recent years, China's furniture and woodworking machinery industry has achieved rapid development, but in the field of high-end products, domestically produced equipment is still relatively lagging behind in terms of its variety, quality, reliability, delivery time and pre-sales and after-sales service. Huge market demand. At present, China is in the key historical period of transforming and upgrading furniture as a traditional industry with high-tech and advanced applicable technologies, and enhancing the competitiveness of China's furniture manufacturing industry with information technology. As a typical key technology for manufacturing and equipment informatization, It is of great significance to carry out the application research of high-end furniture and wood products processing equipment.

As a manufacturing country, China mainly relies on the comparative advantages of labor, price and resources, and the gap between its technological innovation and independent development is far. The manufacturing industry of machine tools such as pipe processing machine tools, pipe bending machines, automatic and automatic pipe cutting machines in China cannot be settled in the status quo. We should seize the opportunity to develop continuously, strive to develop our own advanced technology, and increase technological innovation and talents. Training, improve the comprehensive service capabilities of enterprises, and strive to shorten the gap with developed countries. Strive to realize the transformation of CNC machining machine products from low-end to high-end, from primary product processing to high-precision product manufacturing, and realize the transformation from manufacturing in China to creation in China, from manufacturing to manufacturing.

Equipment At present, China's CNC tube bending machine is in a large enterprise. In fact, some small and medium-sized enterprises cannot afford high-end bending machine products because of the high cost. Therefore, we must consider the cost and cost, and then according to the domestic market demand, the improvement can meet the needs of a large number of small and medium-sized enterprises, and then the high-end customization according to the market environment enables the upper and lower.

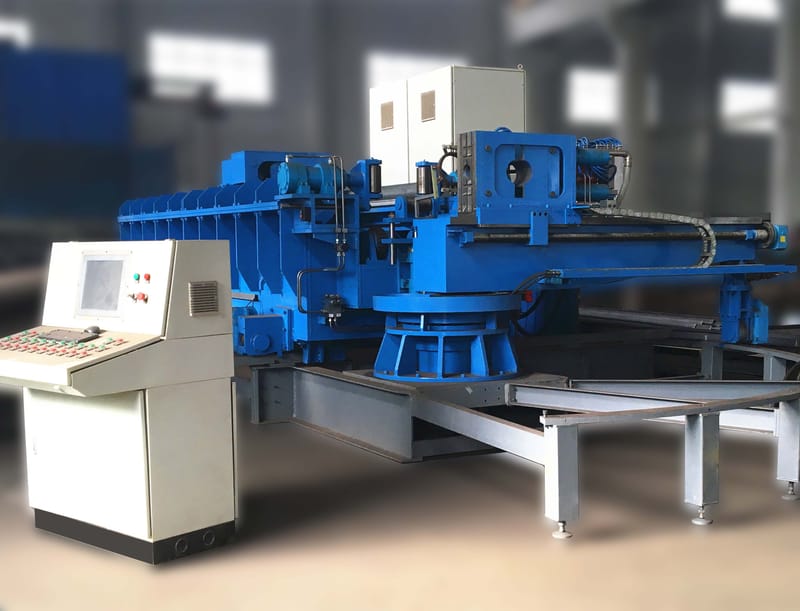

Suzhou Wonsten specializes in the production, CNC tube bending machine, hydraulic pipe bending machine, automatic equipment, etc. The company abides by the business philosophy of "Quality First, Customer Supreme, Honesty Based", sincerely welcome new and old customers. Visit us, all staff will be happy to provide you with a full range of services.