A few years ago, the accuracy of the cnc pipe bending machine was not the main contradiction. Because the process of bending is not so much science, it is better than art. Machine repeat ability is more important. When the setting is satisfactory, the bending machine only needs to repeat the bend. Nowadays, the materials are expensive and the batch size is small. Aircraft manufacturers must look for machines that can be accepted for the first time. Therefore, the first step in producing a good product is to have a sophisticated machine.

The benefits of some precision cnc pipe bending machine are obvious. If the tube is produced for the first time, the productivity will increase and the defective rate will drop. Some of the benefits are not obvious: if a factory has several bending machines, as long as the machines are sophisticated, the bend data of the good work pieces can be shared. This is an important difference between accuracy and repeat ability. A single machine can be repetitive, producing the same product at the same time with the same data; but a group of machines must be sophisticated in order to produce the same product on the same data on any of the machines.

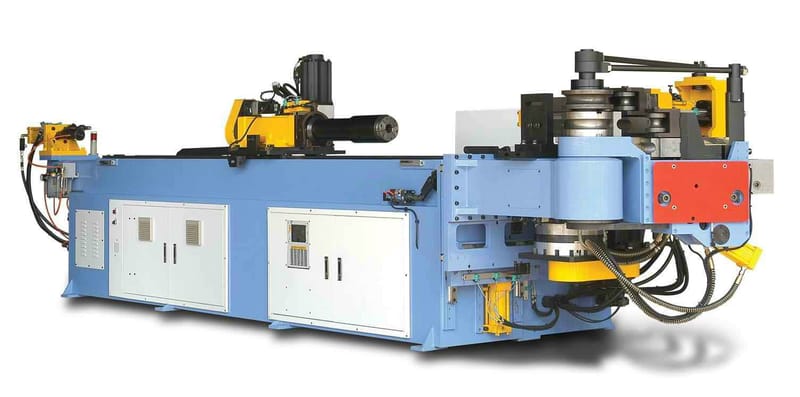

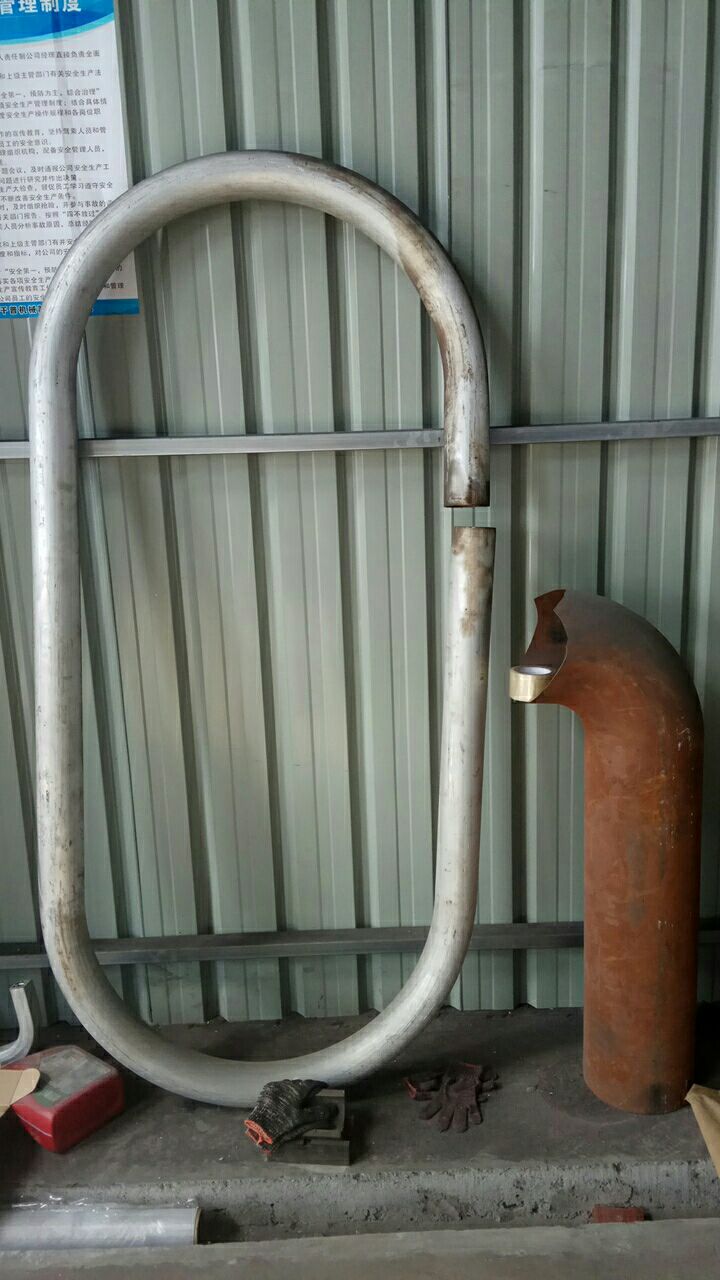

Rotary pull elbows are commonly used in the aircraft industry, where the tubes are formed along a rotating bending die. The production process is relatively simple: pipe positioning, bending, pipe to the next bend position. The accuracy of the bending machine can be divided into three curved tube forming axes: the bending length (DBB), the bending plane (POB), and the bending angle (DOB).

A typical aircraft conduit linear requirement is +/- .010 inches. However, due to the long length of the conduit, it is more realistic to specify the basic accuracy and then accumulate tolerances per foot. The accuracy of modern CNC cnc pipe bending machines is +/- .004 inches, plus an accumulated tolerance of +/- .001 inches per foot. Repeatability is +/- .004 inches for the entire length.

The accuracy of the two rotating axes of the aircraft quality cnc pipe bending machine is +/- 0.01 degrees and the repeatability is +/- 0.05 degrees.

There are several designs on the CNC bending machine to ensure these high precision. On the C-axis, the feedback element (usually a high-resolution encoder) is mounted directly on the elbow arm to directly read the position. On small cnc pipe bending machines, if the encoder is likely to interfere with the pipe, it can be operated by parallel links. The bearings at the joints must have very small tolerances to reduce migration and maintain accuracy.

The B-axis of the bending machine is usually driven by several stages of speed reduction mechanisms. The feedback encoder is mounted on the last stage drive shaft to optimize accuracy and repeatability.

The Y-axis of the bending machine has special problems. Aircraft ducts are much longer than other industries. The most efficient positioning methods are gears and racks. To achieve an accuracy of +/- .001 inches per foot, precision ground racks, high quality gears and direct drive feedback must be used.

Another design requirement for a precision bending machine is that the servo system of the positioning shaft must be "hard". The movement of the mechanical components must be minimal and the electronic servo loop must be positioned and maintained within the required tolerances.

There are other factors that affect the accuracy of the workpiece when using a very precise bending machine. These process variables include various material properties and dimensional tolerances, tooling and tooling settings, lubrication, and weld location.