Why is the arc of the induction pipe bending machine thinner? Experts tell you why

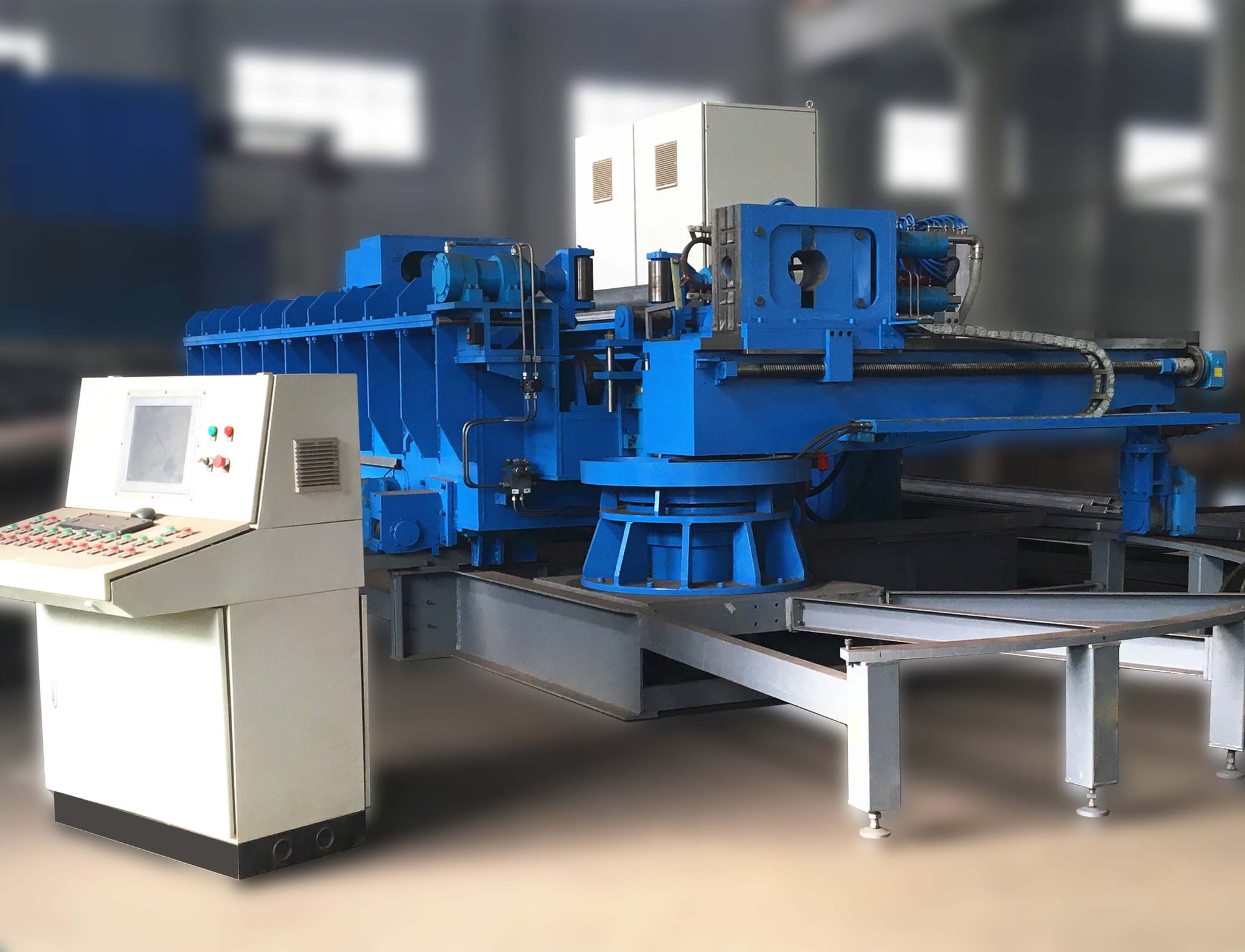

Today, life is full of electrical appliances and machinery, and the pipe bending machine is a general term for a class of pipe processing machinery and equipment. The use of pipe bending machine equipment in industrial processing operations is still relatively common, and it is also a relatively important and important machine. The induction heat pipe bending machine performs the bending of the pipe as well as the bending of the sheet. In the case of pure bending, when the tube with the outer diameter D and the wall thickness t is bent by the action of the external moment M, the outer wall of the neutral layer is subjected to the tensile stress σ1, and the wall of the tube is thin; the inner tube of the neutral layer The wall is subjected to tensile stress σ1 and the tube wall becomes thick. Moreover, the shape of the cross section changes from a circular shape to an approximately elliptical shape due to the action of the combined forces F1 and F2. When the amount of deformation is excessively large, cracks may occur in the outer tube wall, and wrinkles may occur in the inner tube wall. So why is the arc of the induction heat pipe bending machine thinner? Experts tell you why:

The boost and push speeds are determined based on the actual conditions of the bend, matching it to the induction heat pipe bending machine speed. At the same time, it should be checked whether the advancement of the mandrel installation is appropriate, and the necessary adjustments should be made at the time of discomfort. Based on the external bending of the arc of the pipe, the reason should be carefully analyzed. Firstly, the pipe should have a good heat treatment condition. The weld of the seamed steel pipe should not be in the direction of the force of F1 and F2, that is, not clamped correctly. Mold and bending the wheel mold; after removing the factors of the pipe, check whether the pressure of the pressing die is too large and adjust the pressure to be appropriate.

For the newly used mandrel, check whether the diameter is too large. If the diameter is too large, it is necessary to carry out the necessary grinding, and ensure that the mandrel and the inner wall of the pipe are well lubricated to reduce the bending resistance and the friction between the inner wall of the pipe and the mandrel. At the same time, take appropriate measures to avoid machine shake and so on. For the inner side of the arc, the corresponding measures should be taken according to the wrinkle position. If the front cut point is wrinkled, the position of the mandrel should be adjusted forward so that the advancement of the mandrel is appropriate to achieve reasonable support of the pipe when the pipe is bent; After the cutting point is wrinkled, the anti-wrinkle block should be installed, and the anti-wrinkle block should be installed in the correct position. It can be well attached to the bending machine mold, and the pressure of the pressing mold (wheel) should be adjusted to make the pressure appropriate.

In order to maintain the efficiency of the induction heat pipe bending machine and the safety of the machine, an effective machine inspection and maintenance plan must be in place and implemented as required. The life expectancy of relays, solenoid valves or other electrical and mechanical components, the environmental conditions and the complete and thorough preventive maintenance plan. A part can be mistaken at any time due to wear or improper maintenance. Frequent inspections and a good preventive maintenance program can reduce the possibility of mistakes. Parts that are worn or cannot be repaired must be replaced immediately. The cleanliness of the environment around the machine makes any inspections and repairs easier. It is also important to keep the floor around the machine clean and free of debris.