Pipe bending machine usage and transformation

The CNC automatic pipe bending machine industry should seize the opportunity of national policy support and huge market space, increase the intensity of skill innovation and talent training, give full play to the market mechanism to complete the self-optimization of the CNC industry, improve the ability of enterprises to serve, and try to shorten the developed countries. The distance between them is to complete the change of CNC automatic pipe bending machine products from low-end to high-end, from primary product processing to high-precision product manufacturing.

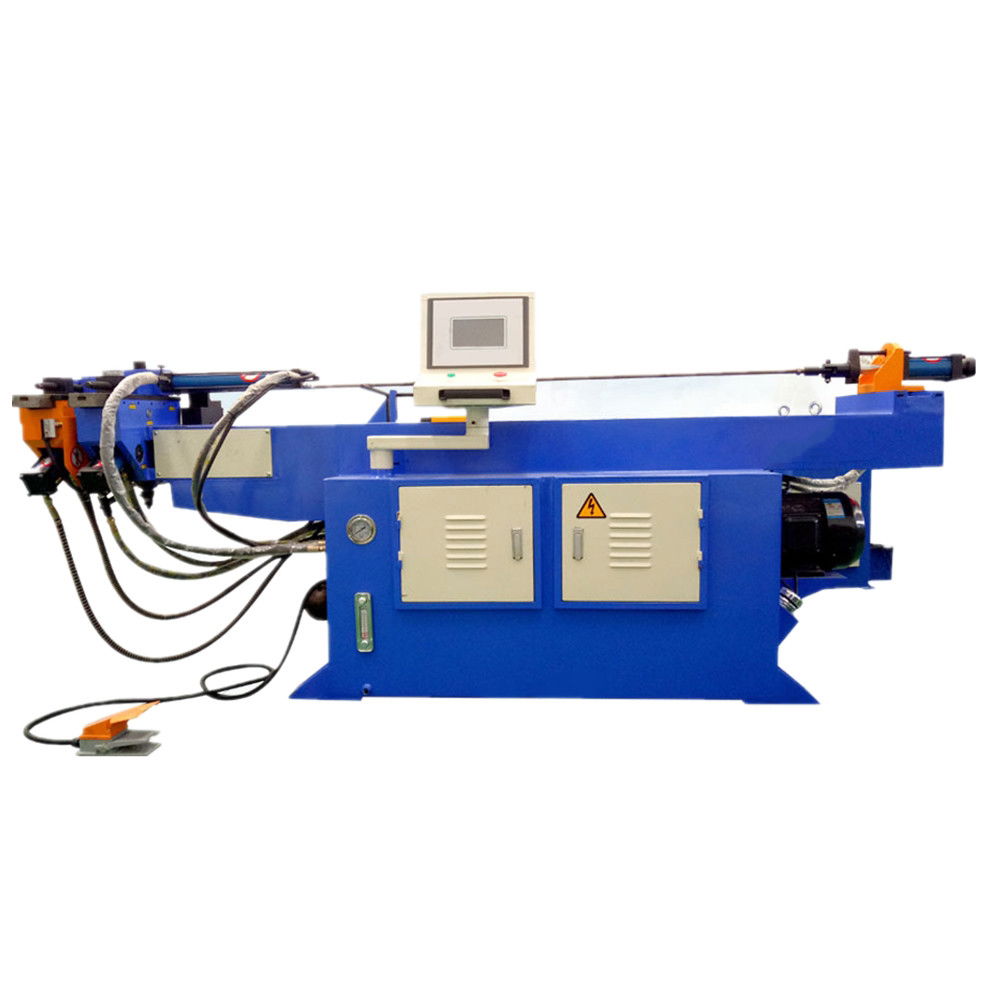

The CNC automatic pipe bending machine is mainly composed of three parts: mechanical part, hydraulic system and PLC control system. The mechanical part mainly consists of a pipe clamping device, a bending pipe transmission device, a boosting device, a bed body and a bending pipe mold. The working principle of the elbow: the elbow mold is fixed on the main shaft and rotates with the main shaft. The tube is fixed on the clamping groove of the fan-shaped elbow mold through the clamping mold, and the movable boosting guide material chute is closely attached to the tube blank. The zigzag outside.

The use of automatic pipe bending machine

Safety Practices: Professional pre-job exercises and assessments can prevent accidental injuries that may occur during production or minimize them. Safety practice programs must be supervised by leaders and managers. Managers must be sensitive to safe work in all their operational responsibilities; proper practice is necessary to achieve maximum protection. In general, employees should be instilled with the safety concept of the working environment and machine operation, and the important rules such as mold equipment guidance, safety equipment and operation methods and personal safety should be paid attention to the individual's safety awareness.

Position of the emergency stop button: On the operation panel: Pressing this button will stop all motor and servo power.

Prevent overload: Confirm the load in the machine operation to prevent overload of the machine components, otherwise it will affect the service life of the machine and the safety of the operator. Indiscriminate use of machinery and equipment will cause overload of machine parts. Excessive load may not be deliberate, but it is easy to happen. This is because the torque required to bend the pipe is greater than the torque of the original design of the machine; please be sure to follow these skill standards, otherwise it will cause serious damage to the machine. The biggest twist is the tensile standard 40Kg/cm2 of the twisted iron pipe.