There are two main methods to measure the radius of pipe bending machine:

1. A more scientific method is to use the Pythagorean theorem, which can actually be used to calculate *. The process is also very simple. First, measure the distance between the two ends of the bend, then assume a right angled triangle, and then apply the Pythagorean formula. This way, it is easy to scientifically calculate the accurate radius of the bend.

2. A more reliable and practical method, but not very practical: first compare the radius of the paper shell circle with that of the bent pipe, and repeatedly adjust the size of the paper shell circle until it matches the radius of the bent pipe. The bending machine then measures the diameter of the paper shell circle with a ruler and converts it into the radius of the bending pipe. Usually, large torque is obtained through a variable speed mechanism, so that ordinary motors can handle it, unless the current simplicity of the pipe material is very cost-effective.

The torque and speed obtained in this way can depend on the actual situation. The servo drive is installed in the electrical control box, with one servo drive controlling each AC servo motor that can rotate the machine shaft. For example, the feeding shaft and angle shaft, each servo driver can be checked by its own display to determine its effectiveness. If the drive pipe bending machine is not in operation or has been overloaded, check the display of this driver. At this time, it will not display or issue an alarm message. In this situation, the machine will not operate.

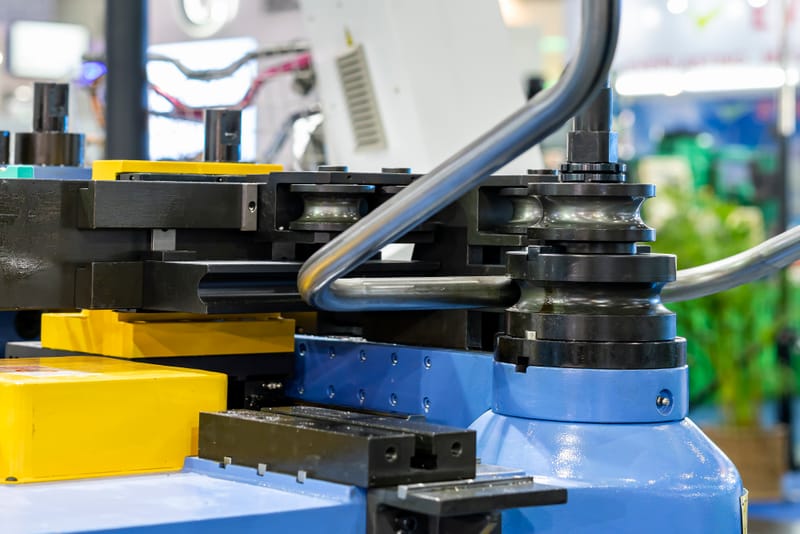

Strong bending ability and high bending quality. The new type of pipe bending machine has a diameter, thick wall, and radius range that is 50% higher than the original pipe bending machine.

The automation of the bending process has been achieved, with high processing efficiency. When used for the original processing of pipe blanks, the entire bending process is manually operated by workers, and the speed of the bending die in and out is the same, resulting in low work efficiency. The new pipe bending machine adopts programmable control, making the bending process automatic. By adjusting the volume and speed, the bending die can be smoothly bent and quickly reset, greatly improving processing efficiency and reducing the labor intensity of workers.

The bending process has high precision. There was originally no angle control device, and the size of the bending angle was solely determined by the operator's visual inspection. The bending accuracy was only ± 5 °, which is difficult to meet the precision requirements of bending products. The new pipe bending machine adopts a rotary encoder and Coco programming controller to automatically and accurately control the bending angle, with an accuracy of ± 1 °, fully meeting the accuracy requirements of pipe bending products.

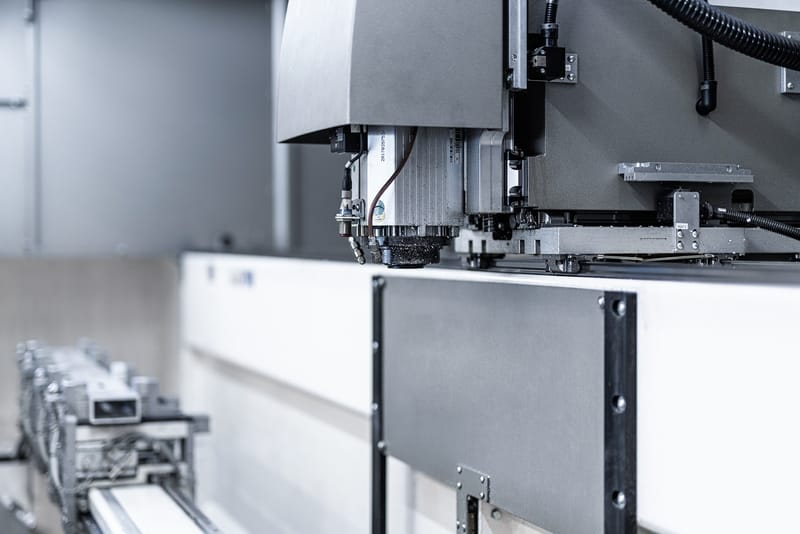

Unmatched Engineering Excellence

Wonsten Group’s core competence is its in‑house engineering capability. Each CNC pipe bending machine is designed using advanced CAD/CAM systems, ensuring that every axis movement and bending trajectory achieves micron‑level accuracy. By integrating servo‑driven motors with proprietary motion‑control algorithms, Wonsten machines consistently deliver complex geometries—even on high‑strength alloys—without sacrificing repeatability. This focus on precision translates into reduced material waste and lower tooling costs for customers.Comprehensive Product Portfolio

From compact bench‑top units for prototyping to heavy‑duty, multi‑axis systems for high‑volume automotive applications, Wonsten Group offers a full spectrum of CNC pipe benders. Their flagship models include:- 38CNC: A mobile work‑cell solution for small‑diameter tubing

- 50CNC5A4S: A mid‑range machine with four‑axis interpolation, ideal for furniture and fitness equipment

- 100CNC6A4S: High‑tonnage, six‑axis bender for shipbuilding and offshore pipelines