Why the global market for fully automatic CNC pipe bending machines is heating up — and what buyers should know

The market for fully automatic CNC pipe (tube) bending machines has quietly shifted from a niche, workshop-level technology into a central piece of modern manufacturing. Recent market research places the CNC/tube-bender sector in the low-to-mid billions today, with multiple forecasts projecting steady, mid-single-digit to high-single-digit CAGRs over the next decade as more manufacturers automate complex bending work.

What’s driving demand right now

Several clear, practical forces explain why buyers are investing in full-auto CNC benders:

- Automotive and EV manufacturing. EV platforms and lightweight vehicle architectures require complex, repeatable bends for battery trays, chassis rails and cooling lines — parts that are difficult to produce reliably without CNC automation.

- Precision industries (aerospace, HVAC, furniture, medical). These sectors need consistent first-pass accuracy and low scrap on thin-wall tubes or exotic alloys; CNC systems deliver that at scale.

- Productivity and labor pressure. Automated feeding, rotation and mandrel control cut cycle times and reduce manual handling — a big benefit where skilled benders are scarce.

- Automation + robotics convergence. Integrating robotic loading/unloading and inline handling is increasingly common, enabling lights-out production and higher throughput.

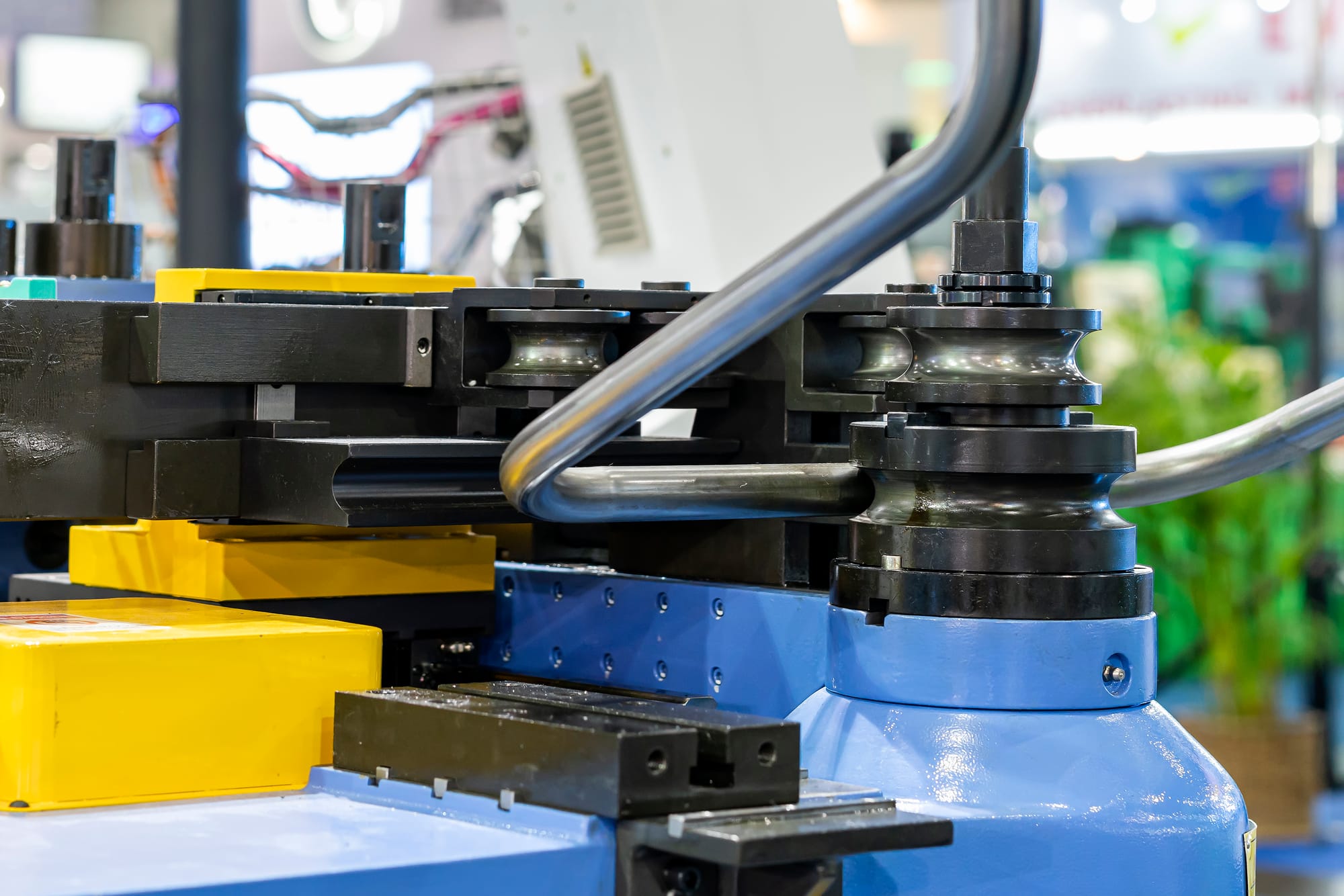

Why fully automatic CNC — not manual or semi-auto — matters today

Compared with manual or semi-automatic machines, a modern full-auto CNC bender brings a predictable set of operational advantages: consistent repeatability across long production runs, reduced set-up and changeover time, and traceable process control for tougher tolerances. For buyers moving into higher mix / lower volume production (think dozens of unique profiles rather than thousands of identical parts), the time-to-value of CNC automation shortens dramatically.

Technology trends worth shopping for

If you’re vetting systems, watch for these practical features — they’re the difference between a machine that simply bends and a machine that reliably produces sellable parts day after day:

- All-electric (servo) drives: better energy efficiency, cleaner shopfloor (no hydraulic oil), faster, more precise axis control. Many users report significant energy and maintenance savings when they switch from hydraulic to electric systems.

- Integrated mandrel and clamp control: essential for thin-wall or high-precision bends to avoid ovality and springback.

- Open, serviceable control platforms: choose vendors with transparent control architectures and proven PLC/CNC software so your maintenance team can diagnose and update without long vendor lock-in.

- Robotic/inline automation readiness: look for standardized I/O, safety packages and end-of-arm tooling options if you plan to run cells with robots or automated feeders.

Why China remains central — and how to avoid common pitfalls

China still produces a very large share of global tube-bending equipment, from cost-focused production benders to increasingly sophisticated CNC systems. Buyers benefit from wide price/feature choices and fast lead times, but must be disciplined about qualification: insist on cycle-time data, parts-per-hour metrics, material-specific test bends and verifiable references in your industry.

As an example of a Chinese supplier that spans this range, WONSTEN GROUP offers fully automatic CNC tube benders and related equipment and works with international buyers to configure machines for target cycle rates, alloy mixes and automation layouts. Treat any vendor recommendation as a starting point — validate with production trials on your real parts.

Practical buying checklist (what to request from vendors)

- Real test reports: sample bends on your exact tube material, OD, wall thickness and tooling.

- Throughput metrics: kg/hr or parts/hr at quoted tolerances and changeover time.

- Energy and maintenance data: for electric vs hydraulic options.

- Service footprint & spare parts lead times: crucial if you’re running multi-shift production.

- Automation readiness: safety, robot integration, and data outputs for Industry 4.0 systems.

Bottom line

Fully automatic CNC pipe bending machines are no longer a “nice to have” for high-mix, precision manufacturers — they’re a business enabler. Whether you’re reducing scrap on thin-wall HVAC coils, scaling EV chassis components, or moving toward lights-out cells with robotic feeding, a modern CNC bender pays back through consistency, lower labor dependency and faster ramp-ups. If you’re evaluating suppliers, compare machines on real productivity numbers and energy/lifecycle costs — and consider partners like WONSTEN GROUP as one of several qualified manufacturers to validate with sample runs and technical references.