How to avoid failures in daily use of pipe bending machine

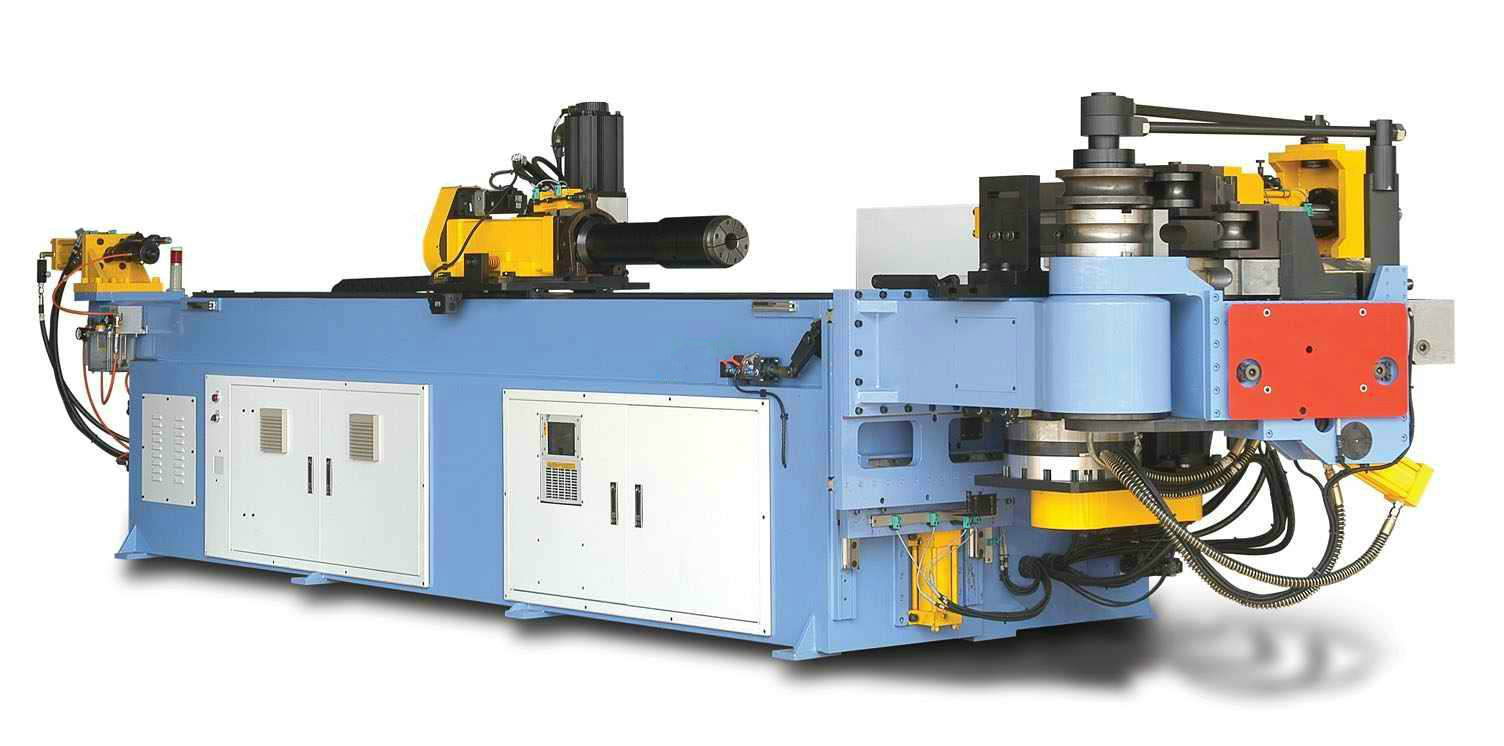

Today, with the development of scientific and technological skills, the pipe bending machine equipment is now more and more sophisticated in terms of quality and skill in the pipe processing machinery such as hydraulic pipe bending machine and automatic pipe bending machine and pipe cutting machine. It's not like the birth of a new product and new skills, we are all in the state of exploration, so the performance of the machine is relatively fragile, but today's pipe processing equipment is stable and regular, so After purchasing the machine tool, you only need to carefully maintain the machine tool, which can be used for a long time.

But what problems do the bending opportunities often present in daily use? In fact, these problems have already been mentioned in the previous log skills article. Today, we are talking in the old saying, there is usually a hydraulic area where the problem is caused. Because the machine is bent, the pipe is cut by a metal circular saw. Many small iron pins. If these iron pins are not cleaned, they will be directly processed into the bending machine to process the elbows. Many of the bending machine molds have a core rod tortuously. Because the fullness is not high enough, they will wrinkle or collapse. And so on.

In this way, when the pipe bender inserts the pipe into the mandrel, the small iron pin will fall out, and the iron pin that has not been trimmed will fall into the fuel tank inside the fuselage. We all know that the hydraulic pipe bender selects the oil pump input hydraulic pressure. The oil is supplied to the hydraulic power by a solenoid valve. Therefore, most of these iron pins will be filtered by the filter screen inside the oil inlet pipe after entering the fuel tank, but a small part of the iron pin will enter the oil pump, so that the iron pin sucked into the oil pump will enter the electromagnetic field. Inside the valve, these iron pins are blocked by the hydraulic solenoid valve due to the inability to flow in the solenoid valve, and the hydraulic oil cannot flow, which may cause a corresponding malfunction, resulting in the hydraulic bender not working properly.

Even if this phenomenon is presented, there is no need to panic. Just press a button on the control panel to manually press a certain action, then look at the indicator light on the solenoid valve to see which solenoid valve is not working, and then close the movie. Then use a 4mm Allen key to remove the solenoid valve attached to the oil separator. After cleaning the solenoid valve with clean fire oil, clean the inside with an air gun and clean the iron pin inside, then install it and handle it.