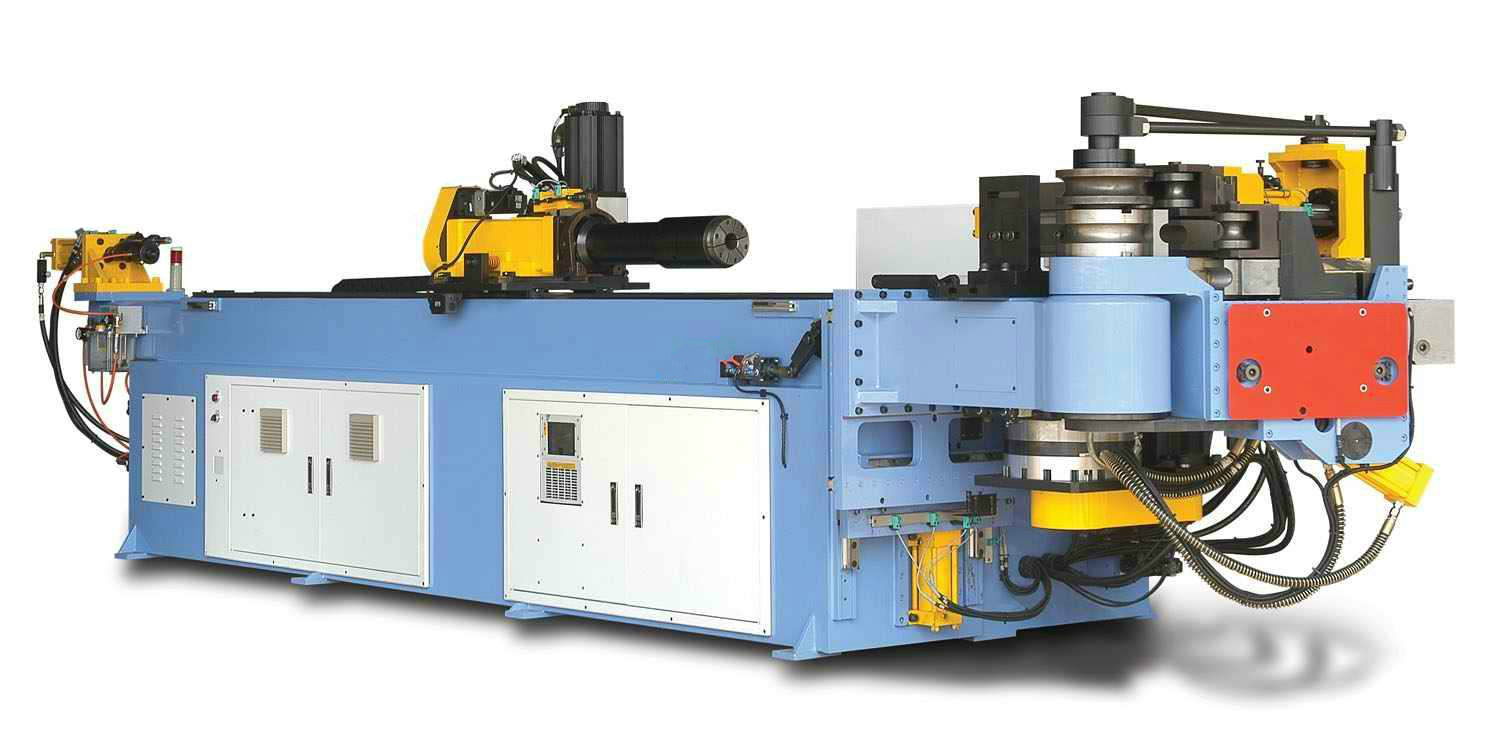

Application range and induction heating of pipe bending machine

During the working process of the special frequency cooling tower of the bender, the cooling medium (soft water, oil or other liquid) is driven by the main circulation pump to circulate between the heat exchanger and the cooling equipment, and the spray water is evenly sprayed on the heat exchanger. A uniform water film is formed on the outer surface of the heat exchanger, and the cold air enters the tower from the air inlet below the tower body, and flows back through the heat exchanger surface with the spray water. In this process, there are two heat exchange methods, namely, cold The heat transfer between the air and the cooling medium and the heat exchange of the transpiration of the spray water, the hot and humid air after the heat is absorbed by the fan to the atmosphere, and the rest of the spray water flows into the water tank at the lower part of the tower body, and is then transported by the water pump. To the spray system. In this way, the cooling medium in the heat exchanger is cooled and cooled.

1. Bending machine induction heating and metal melting equipment, such as: high and medium frequency quenching equipment, medium frequency power supply and electric furnace, induction diathermy furnace, holding furnace cooling, industrial solution cooling, such as quenching liquid, electroplating liquid, etc.

2. Cooling of various reactors and condenser circulating water in the chemical industry.

3. Cooling of large motors, diesel engines, rectifier equipment, electric welding equipment, hydraulic stations and continuous casting equipment.

4, metal die-casting molds, injection molds and other large mold cooling.