Ways to avoid noise from the pipe bending machine

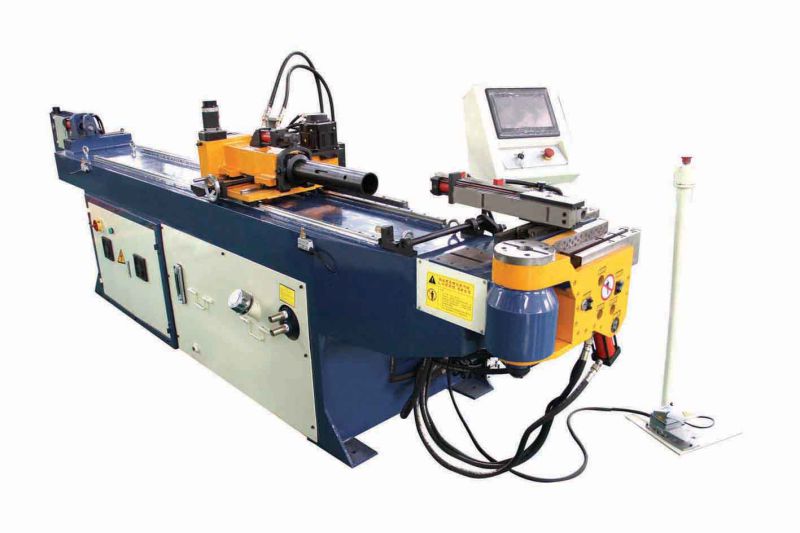

Whether in the automotive parts or furniture production, the use of pipe bending machine is very important, the primary effect of the pipe bending machine is to be able to process the bending into any desired curvature, and the operation is very convenient and safe. . Many pipe bending machine on the market today use microcomputers for production and operation, and the smart chips used also have high sensitivity.

The tube bending machine uses the encoder to control the angle of processing, so the processed elbow is very accurate in angle, which is precisely because it makes it widely used in the profession. However, the biggest disadvantage of the bender in the process of processing is the relatively loud noise, which is the primary reason why it can not be selected in many occupations. How to deal with this problem effectively?

Many manufacturers choose the tube bending machine, not only the quality of the processing, but also the requirements for the comfort of the operation. The domestic bending machine also has requirements for noise, and the power is relatively large. Generally, it is above 80dB. If it is used in a lower temperature environment, it will not only present a large noise, but also a consensus phenomenon.

The frame of all the pipe bending machine is basically the structure of the box and is welded. It is similar to the appearance of the speaker, so the noise is also certain. If it is severe, the noise will be enlarged because the temperature is lower. The grease of the lubricating oil in the pipe bending machine will also increase, and the sealing ring in the equipment will also increase the resistance to shorten the movement, and the noise will be formed.

When the frame of the pipe bending machine is welded, the quality of the welded parts must be ensured, and the deformation state of the welding may be minimized, so that the noise of the bending machine can be appropriately lowered, and when the sealing ring is selected, It is best to choose a grease that is resistant to low temperatures, which is critical to the presentation of the bender noise.